Given that it selected hydrogen as the way to reach its net-zero emissions goal, why is Airbus working on hybrid-electric aircraft batteries?

We have looked at the EcoPulse project before. This is a joint project between Airbus and Daher, which is a smaller aircraft manufacturer. The partnership also includes Safran, maker of aircraft engines and other key aircraft components. A Daher TBM 900 is the testbed aircraft in this project. And according to Airbus, the program’s goal is for the aircraft to fly this year.

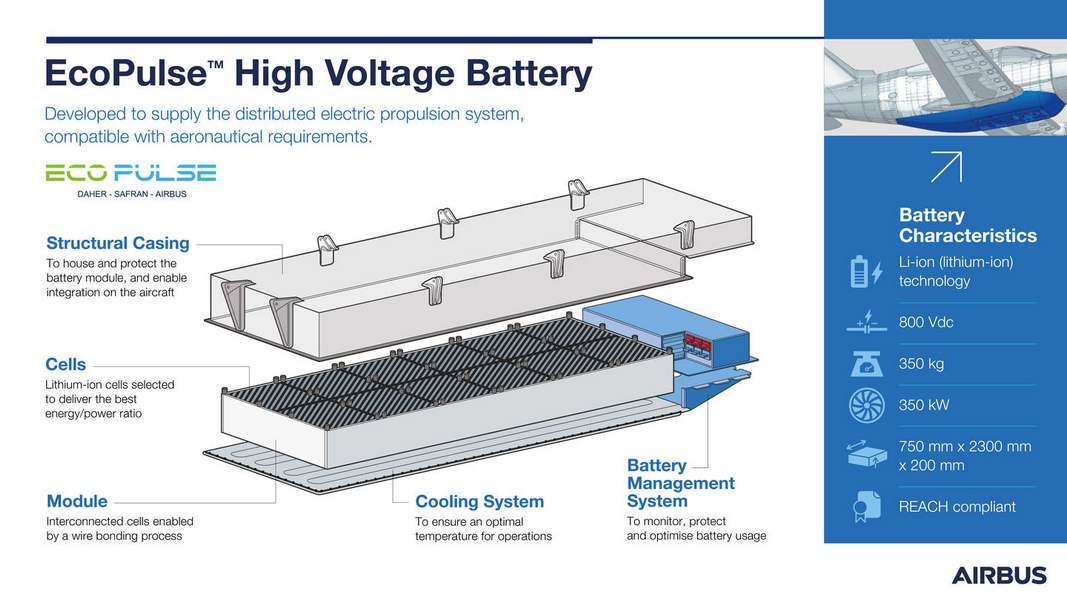

Interestingly, it is Airbus itself that is in charge of the design and integration of the batteries in this project. The EcoPulse aircraft will incorporate a purpose-built battery compartment, under the pressurized fuselage. This will incorporate the batteries themselves, plus control electronics and a cooling system.

Thermal runaways with lithium-ion batteries are extremely dangerous. The electronics and cooling are vital, to ensure runaways don’t happen. And with the right structure and layout, Airbus can guard against the worst effects of thermal runaways, if they DO happen. Beyond these challenges, Airbus has to evaluate the weight and output of the batteries. For the EcoPulse, the high-voltage battery installation weighs 350 kg, runs at 800 Volts DC and delivers up to 350 kilowatts.

Hydrogen Propulsion AND Batteries?

But on the face of it, such a project is somewhat at odds with the rest of Airbus’ sustainability projects. Airbus had another hybrid concept, called the E-FanX (below). This project started in 2017 – and ended in 2020. A few months after that, Airbus launched the hydrogen-based ZEROe initiative. To analysts, this was a message that Airbus didn’t view hybrid propulsion as a viable proposition, for an airliner-sized aircraft.

And subsequent statements from the manufacturer seemed to verify this assessment. So why is Airbus a part of this project, and why is it working on batteries? Airbus itself provides the answer, about halfway down in its press release. Essentially, it is because the manufacturer needs this technology for its future aircraft – including those using hydrogen. Airbus says:

“Not only is this power level sufficient for driving EcoPulse’s six electric propulsors, depending on the test conditions, but it also happens to be similar to what would be needed for an airliner’s non-propulsive secondary systems. Airbus is exploring the latter separately as part of its “micro-hybridisation” research, with the high-voltage battery concept being a key ‘technology brick’.”

New Roles For Batteries In Airbus Aircraft

In essence, micro-hybridisation is a generic term, encompassing efforts to use electricity to replace other aircraft systems. Boeing got the ball rolling in this regard, with its 787. By eliminating (or actually, severely limiting) hydraulics and the need for bleed air from the jet engines, aircraft designers can simplify many systems. Ultimately, the goal is to improve efficiency.

So Airbus is working on batteries because it wants to go a lot further. With the EcoPulse battery setup, plus a turbo-generator that Safran makes, Airbus could replace the APU in future airliners. Safran and Airbus call this the e-Auxiliary Power Unit, or e-APU. It is worth pointing out that a typical APU IS a turbo-generator, i.e. a gas-powered turbine, driving a generator. But the e-APU’s turbo-generator should be smaller, simpler and hopefully, more efficient.

Aircraft with new propulsion technology need new aircraft systems to support them. Airbus is still targeting to put a hydrogen-electric or hydrogen-burning aircraft in service in the 2030s. The e-APU and its lithium-ion batteries will be essential in either design. Plus, new features like electric taxiing put more demands on the electric systems of future aircraft.

So with the EcoPulse project, Airbus has a chance of an early test to this element of the technology. And this is on top of other benefits in the EcoPulse setup, like distributed propulsion. Even if batteries aren’t yet suitable as a means of propulsion for airliners, Airbus clearly thinks they are part of future aircraft.