Unlike other startups in electric propulsion, MagniX are going electric using a more measured approach: designing the propulsion system. And then fitting it to existing, flying aircraft!

We have seen companies using existing aircraft as testbeds, for new systems. This is quite normal. But for most, the testbed is just that. They then aim to mount their equipment on something new. Something that doesn’t yet exist, that is. MagniX are going electric in a different way.

The problem with designing an aircraft from the ground up, is that it needs a lot of time. Many companies feel it’s worth it, for efficiency reasons. Users of electric cars will know how big a factor weight is. The development of electric technology is largely about the weight of batteries. Going electric is fundamentally about going on a diet, but MagniX sees the opposite end of the coin as well.

The problem with doing it all at once, is that you run the risk of doing nothing particularly well. Starting in Australia in 2009, MagniX decided they were going to design aviation-specific electric motors. Later, they opened an American engineering centre in Washington State. And yesterday they announced that they are consolidating their operations at a new facility in Everett. It’s not far from Boeing’s assembly plant.

Electric Planes with MagniX Power

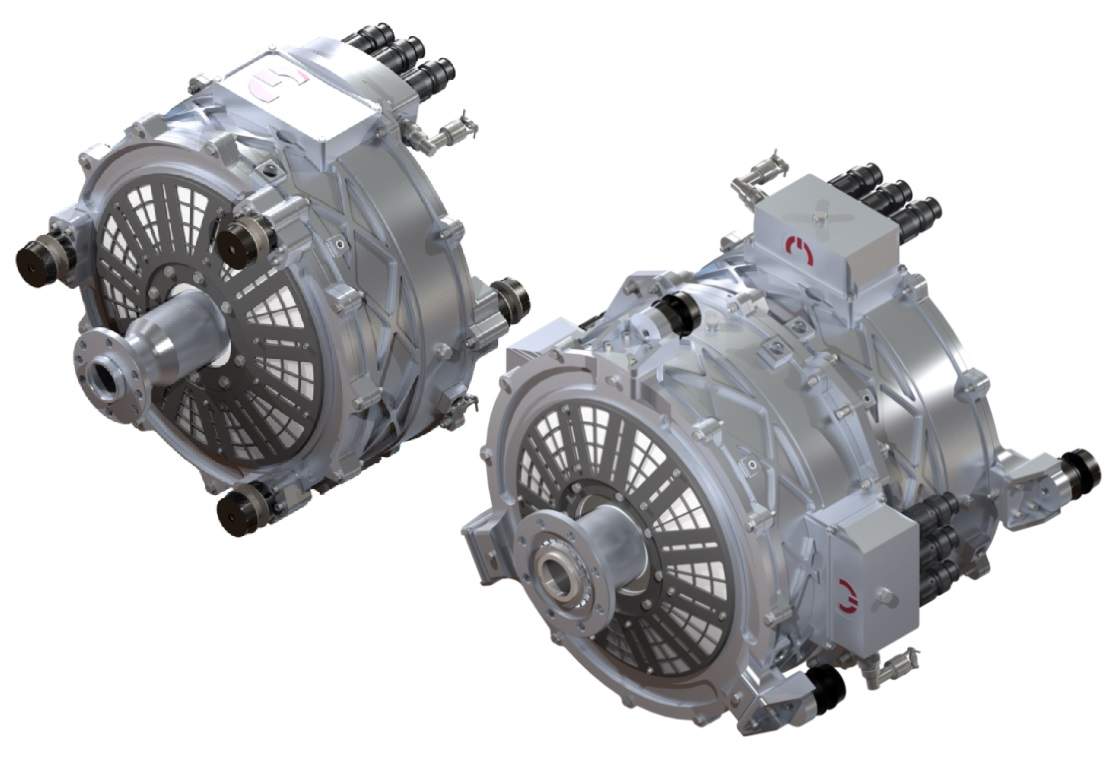

You may remember Harbour Air’s ‘eBeaver’, a De Havilland Beaver that flew on electric power in December 2019. The aircraft flew with a magni500 motor. This is the biggest of MagniX’s electric offerings, having 560 kw (750 shp). They also make the magni250, with half the size and power. However that first test flight was mostly a dress rehearsal.

In May 2020, MagniX flew a Cessna Caravan on the same electric motor. In both cases, the motor had replaced a turboprop (Harbour Air’s Beaver had lost its radial engine already). But the ‘eBeaver’, loaded to max gross-weight with batteries, could only fly for 15 minutes, with a 25-minute reserve. The Caravan, on the other had, could fly 4-5 passengers 100 miles away, with the same reserve. That was in its initial prototype configuration.

Obviously it will take time and effort to certify these aircraft to fly commercially. But the prospects of the technology are very tempting. MagniX has gathered some statistics, to see the viability of aircraft with electric power. The company estimates that 45% of flights in 2019 were 500 miles or less. They feel that this range is well within reach, with the right platform.

Electric motors are a good fit, as replacements for turboprops or even piston engines. In the Beaver, MagniX’s motor is closer, in shape and size, to the original Wasp radial engine, than the Turboprop! It is lighter, however. And of course electric motors have constant torque curves, from very low (sometimes zero) rpm. Which, in this case, means that aircraft with electric motors like MagniX’s, don’t need constant-speed propellers. This saves even more weight.

More Projects – And Hydrogen?

The next aircraft to fly with MagniX’s electric motors, may be one of Harbour Air’s DHC Twin Otters. The Canadian airline has announced very ambitious plans. Ultimately, it wants to electrify its entire fleet of Beavers and Twin Otters. But MagniX has more plans. And they don’t include just existing aircraft.

MagniX will also provide engines for the Eviation Alice electric aircraft. This new design will use three of the smaller magni250 motors. It is a very interesting design in itself, which would have had its first flight already. Unfortunately, a battery fire destroyed the prototype fuselage in January 2020. Eviation now hopes to fly its newer prototype in 2021.

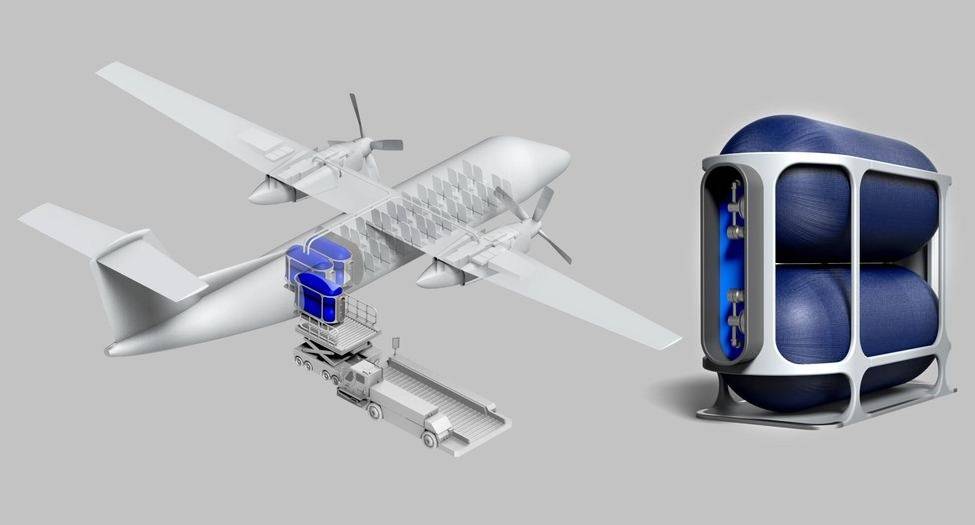

But the most ambitious project that will involve MagniX’s electric motors will be Universal Hydrogen’s programme. This company is developing a means to store hydrogen, in standardized tanks, that can also serve as aircraft hydrogen tanks. The plan is to convert a De Havilland Dash 8-300 (also known as Q300)! It will have two electric motors where the turboprops are, hydrogen tanks in the rear of the fuselage and a hydrogen fuel cell, to generate electricity.

The amount of experimentation in electric aviation today is truly impressive. We have seen how Airbus are working on related concepts. Other companies of all sizes have very impressive ideas, at various stages of development. And as aircraft begin to fly, they can only get better. MagniX seems to provide a vital component in this electric puzzle – one which takes many different shapes!

MagniX’s website