Most people have never heard of the Boeing 7J7. And yet this rather unusual design once looked set to replace both the 727 and 737!

In the neat and tidy way we like to organize aircraft types, it was the 757 that replaced the 727. But in practice, the 727 remained in service in many parts of the world (including the US) well into the 2000s. That’s 20 years or more after the 757 entered service, in 1983. Back then, Boeing was still about a year away from flying the 737 Classic (-300/-400/-500) for the first time.

But the manufacturer didn’t want to rest on its laurels. The single-aisle market back then included the McDonnell Douglas MD-80 family, and Airbus was busy working on what would become the A320 series. Boeing was looking for a technological leap to keep it ahead of the pack, and that’s where the 7J7 came in.

High-bypass turbofans were not new in the 1980s. But they were “coming of age”, with their advantages in efficiency there for all to see. If you’re unfamiliar with these terms, a turbojet is (simplistically speaking) the simplest form of a jet engine. A turbofan is essentially a turbojet whose fan (usually at the front) envelops the turbojet, but also propels air rearward, without sending it through the engine. However, this fan is still enveloped by a cowling.

Boeing 7J7 – A New Concept

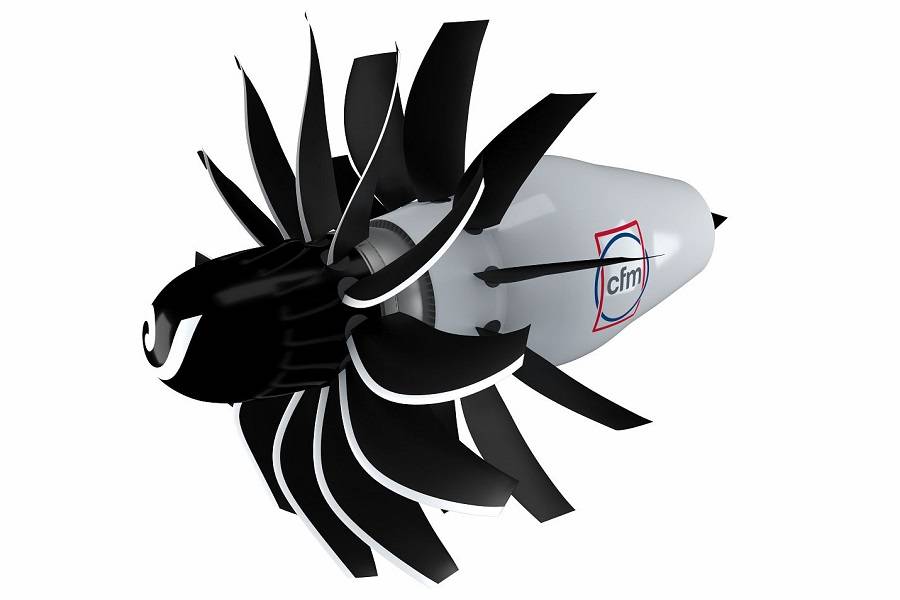

By contrast, the Boeing 7J7 would have had a propfan, also known as an unducted fan. In this setup, the fan doesn’t sit in a cowling. This allows the fan to be much bigger. With turbofans, the higher the amount of air that goes around the jet core, the more efficient the engine generally becomes. This is what engineers call “the bypass ratio”. And thanks to their lack of cowling and larger overall diameter, propfans have higher bypass ratios.

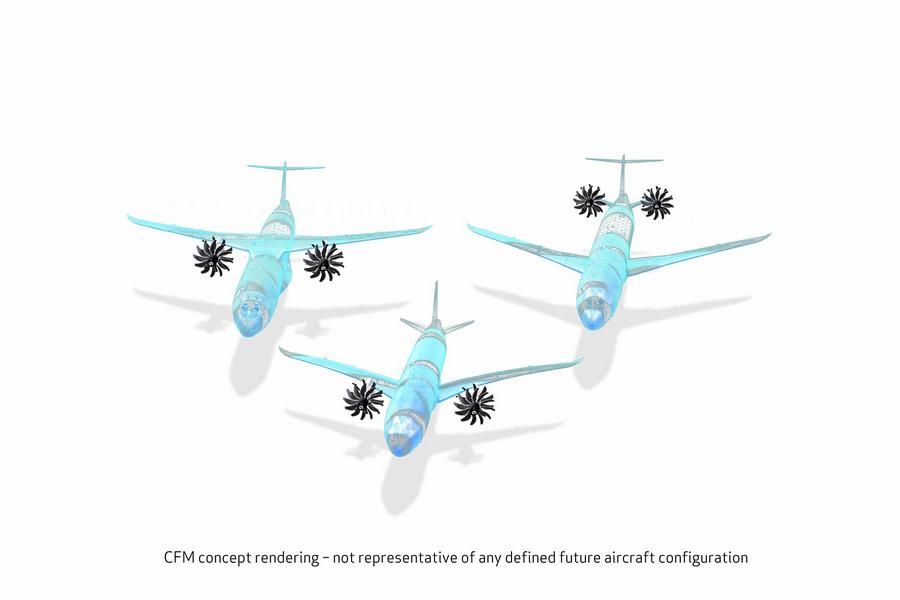

So already in the mid-to-late 1980s, Boeing was studying the 7J7 as a platform that would take advantage of this promising technology. The dimensions of the fans meant that tail-mounting the engines made more sense. This partially dealt with another shortcoming of these engines, which was noise. In regular turbofans, enclosing the fan helps reduce its noise. And it also helps a lot with safety, if a blade breaks.

Boeing knew that the technology around these engines would take time to bear fruit. But the aircraft itself would also be state-of-the-art. It would use fly-by-wire and the structure around the rear of the plane would use composites. Also, Boeing promised a quiet cabin, to quench fears about the noise of the unducted fans.

Playing it safe, Boeing wanted the 7J7 to start off as a small aircraft. And this brings us back to the 727 Vs 757 story. The latter design is bigger than the former because Boeing expected 727 operators to “upsize” to the 757. Some did this; many didn’t. Among the 737 Classics, the 737-400 would eventually pick up some of the slack.

The Boeing 7J7 And Two Engine ‘Suitors’

But for the 7J7 to work, Boeing depended on those propfan engines. A number of aircraft manufacturers busied themselves developing such engines. The main two were GE and its partner, Snecma (later Safran) and Pratt & Whitney with Allison. GE and Snecma were already partners in the CFM venture at the time. Allison would eventually become part of Rolls-Royce’s American division.

The two engines were the General Electric GE36 and the Pratt & Whitney/Allison 578-DX. There were some differences between them, the most important being the gearbox – or lack of one. The 578-DX was a geared design, while the GE36 wasn’t. And this is where we begin to see why the Boeing 7J7 concept remained a concept.

In terms of efficiency, Pratt & Whitney’s geared design was better. But back in the 1980s and early 1990s, many were sceptical about using reduction gearboxes in jet engines. The design of the P&W/Allison 578-DX propfan was based on Allison’s turboprop engines. Both Allison and P&W had plenty of experience with turboprops and gearboxes. But of course, the gearbox for the 7J7’s engines would need to handle more power.

Despite a possible 10% advantage for the 578-DX’s gearbox design, Boeing selected General Electric’s GE36 for the 7J7. Ultimately, it didn’t matter. The gearbox wasn’t the only concern about these engines. Development delays, worries about the noise, plus the loss of an exposed blade, ultimately forced Boeing to freeze the program indefinitely. McDonnell Douglas (who favoured the P&W/Allison engine) also planned an MD-80 derivative with such an engine. This one didn’t go anywhere, either.

Fast-Forward Three Decades…

Both programs were abandoned in the early 1990s. And here we are, 30 years later, with many of the same aircraft still flying – albeit with newer engines. But a lot of water has gone under a lot of bridges since. Engine manufacturers now have more knowledge of jet engine cores, turbine blades AND gearboxes.

Boeing hasn’t used the 7J7 designation since the 1990s. But General Electric and Safran (formerly Snecma) are working on a project called the RISE Open Fan. Under the CFM joint venture banner, this engine is a more refined development of the propfan concept. The fan is now at the front and does not feature two counter-rotating disks. Rather, the front disk rotates, with the second set of blades being stationary (stators), changing pitch as necessary.

But unlike the GE36 of the Boeing 7J7, the CFM Open Fan employs a gear reduction design. This could become a point of contention between CFM and Pratt & Whitney, which claims ownership of a patent covering the design. This is a rather important and somewhat unpredictable part of the story. Other engine makers are also working on geared turbofan designs, so we will definitely hear more about this, soon.

Timing, Other Technologies And Competition

Also, the timing of these developments is key. Ultimately, Boeing failed to make the 7J7 a reality, because the engines were too immature. Now, Boeing’s new aircraft plans could face similar hurdles. Analysts believe that Boeing’s new project when it comes, will aim to enter the market at the end of this decade. But the CFM Open Fan won’t realistically be ready for another 5-6 years.

As with the Boeing 7J7, the newer Open Fan engine promises a 20% efficiency gain over today’s best high-bypass turbofans. However, by the time the Open Fan enters service, current turbofans could gain another 10% in efficiency. The open rotor designs should still enjoy a roughly 10% gain. But this assumes no serious losses from the new engine installation.

At the same time, we see companies like Embraer, planning to introduce turboprops with very similar engine mounting solutions. The possibility of some technology transfer in aircraft systems, between aircraft with similar layouts, is hard to ignore. However, Boeing is no longer partnering with Embraer.

But supply chains between manufacturers overlap considerably, and some technology transfer (or concurrent development) is inevitable. When the next Boeing or Airbus comes, we really don’t know if it will be close to what the 7J7 looked like. But between these developments and others around hydrogen, we can expect future airliners to be different.