Airbus has a dedicated flight testing arm, that it calls the Flightlab Team. And an Airbus A350 is its most recent new Flightlab. But it won’t be the last!

Airbus is keen to push its image as a strong, engineering company. They are also pursuing some demanding new technological fields, that call for some out-of-the-box thinking. The company wants to inspire the next generation of engineers and designers. The rendering you see below is from the 2019 Royal International Air Tattoo air show, in Britain. It features electric motors and hybrid or hydrogen propulsion, concepts that Airbus later featured in more detail. It also features ‘bio-mimicry’, i.e. the study and imitation of animals and birds.

The Airbus Flightlab is the team within the company that takes such concepts and makes them real. And that includes bio-mimicry. But ultimately, new concepts and ideas need testing on real aircraft. Yes, flight modeling in increasingly powerful computers can do a lot of the legwork. These models can also help eliminate some dead-end ideas. But in the end, to approve something for use, you need a real plane, with real pilots. This is what Airbus’ Flightlab is for.

We have already seen one, rather striking-looking Airbus Flightlab aircraft recently. It was the Airbus BLADE, a modified A340, with sections of a laminar flow wing. But this wasn’t the only work this particular A340 did. It had previously tested electronics and other technologies for the A350 programme. And now, the Airbus Flightlab team have an A350 in Colorniers, 12 km away from Toulouse. This bird will do test work for the next generations of aircraft.

Some Testing Goals For Airbus Flightlab

Of course these aren’t the only two Airbus aircraft that the Flightlab Team uses. They also have A320s, and there are now plans for something newer, and different. But in general, the Flightlab team has four broad fields, for which they do research. In order, they are:

REDUCING EMISSIONS: we saw a great example of this with the BLADE laminar flow programme. This Airbus Flightlab programme proved a 50% reduction in wing friction. And this amounts to a 5% reduction in CO2 emissions. This is a veritable leap in efficiency, that could literally reshape future airliners. The Flightlab team will need to follow it up with a look at the wings performance, with contamination.

IMPROVING THE PILOTING EXPERIENCE: this is work relating to reducing the workload of the pilots, boosting safety. The new Airbus A350 Flightlab is already getting new instrumentation, for this purpose. They include optical sensors in the engine inlets, and separate sensors that can measure engine emissions, in flight!

That’s not all. You may remember the Airbus ATTOL. This Airbus Flightlab programme demonstrated an automatic take-off, landing and taxi cycle. In Airbus’ own words, it is a programme to take us from automation to autonomy… eventually. But perfecting such a system involves many more sensors, including LIDAR. Think of this as a laser version of radar. Finally, the A350 will demonstrate optical ice detectors, to help pilots recognize icing.

Passenger Comfort And Safety

INCREASING CONNECTIVITY: that’s primarily about us, the passengers. The Airbus Flightlab team is looking at ways to implement 4G/5G connectivity for passengers. These could include testing for some seriously cool technologies, like airborne laser communications. But connectivity has plenty of applications for pilot crews as well. We have seen moves to transmit CVR/FDR data to the ground, in regular intervals. While something like this would have been prohibitively expensive in the past, connectivity for passengers could make it possible.

FOSTERING TRUST IN AIR TRAVEL: that, unfortunately is very relevant today. The Airbus Flightlab team is looking at ways to ensure proper sanitation of aircraft. Even as they are today, airliners have air filtration systems as good as or better than those of hospital ICUs. But Airbus is also looking at things like special ultraviolet lighting, that could improve sanitation further. They’re also looking at procedures to facilitate disinfection during quick turnarounds.

Airbus Systems And Flightlab

The Flightlab programme is also reviewing more complex systems, for long-term aircraft goals. These include the electrification of flight, for electric and hydrogen-powered aircraft. For instance, the team flew an ‘electric flight test demonstrator (e-FTD) to trial electric air-conditioning. This is part of eliminating the need for bleed-air and hydraulic systems, simplifying aircraft. Of course Boeing’s 787 designers already know something about this…

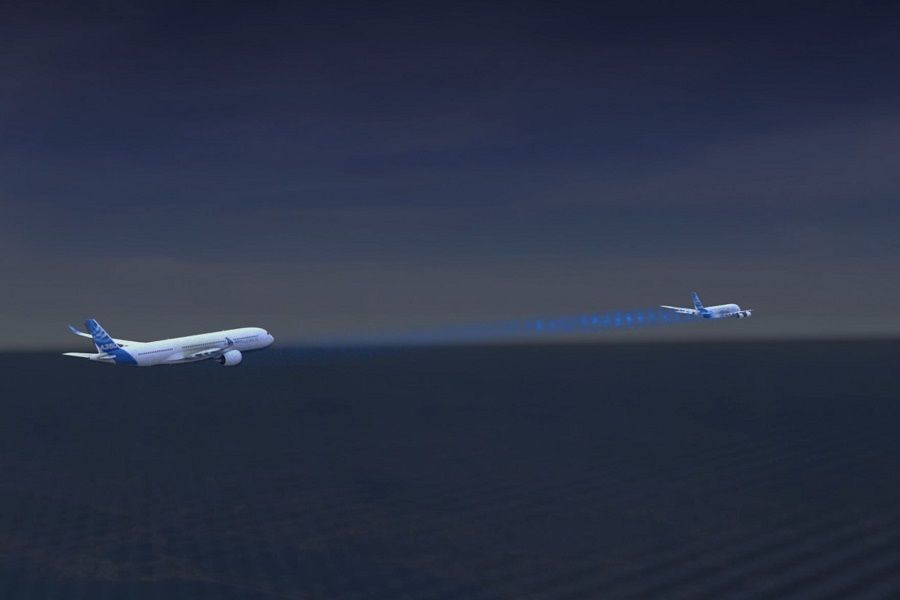

Of course the above would fall under the ‘reducing emissions’ category. The same is true for the ‘fellofly’ programme. This also involved the Flightlab team’s Airbus A350. This project aims to help aircraft save fuel by flying in each other’s wakes, like migratory geese! And yes, they’ve actually tried it, successfully. The previously-mentioned multitude of sensors, measuring real-time emissions, would come in handy when evaluating such a technology.

Helicopters, Urban Air Mobility And… Space?

Flightlab is now also working on other Airbus departments, including helicopters. Fields of interest for the team include adding a form of hybrid propulsion to their helicopters. This would work as a backup, in the event of power loss. Having an electric motor capable of providing some power during auto-rotation, could make the difference in a survivable landing.

Other helicopter tasks for the Airbus Flightlab team include measuring noise levels with different rotor/blade setups. And for urban air mobility, they wish to try more electrical systems, and simplified flight controls. These electrical systems could form part of the backup system mentioned previously. Or they could be an entirely separate system. Flightlab works with other Airbus teams, working on scaled urban air mobility prototypes.

And finally… space? Probably not, but the programme makes reference to Airbus Defence and Space division. This could include technologies relevant to the MRTT, the Eurofighter, UAS and other systems. There is also DeckFinder, a helicopter landing system. Airbus develops it initially under its military/UAV auspices, but Flightlab could certainly work on it for civil/commercial use.

Thierry Fol, Cross-Divisional Airbus Flightlab Leader, summarizes this multitude of programs, thus:

“You can’t test tomorrow’s aircraft technologies on today’s in-service aircraft. And advanced modelling is not enough to deliver proof of concept either. We need flight testing in a real-world environment.”

1 comment

Andre T

How much did AirBus pay for this advertisement oh I mean article?