Authorities in Italy accuse two companies and seven individuals of risking aviation safety by supplying flawed parts for Boeing aircraft.

This is an issue that goes back to 2021. In October that year, Boeing revealed that a number of 787 components that it got from a subcontractor, weren’t up to standard. This wasn’t a new problem. Boeing discovered that it had been assembling 787s with these parts for the previous three years!

Boeing got these parts through contractors like Leonardo and Spirit AeroSystems, but these companies, in turn, got them from another subcontractor in Italy. That company was called Processi Speciali, and later went bankrupt.

Then a newer entity, called Manufacturing Process Specification (MPS), replaced Processi Speciali. The owner of MPS is Antonio Ingrosso, while his father, Vincenzo Ingrosso, previously owned Processi Speciali.

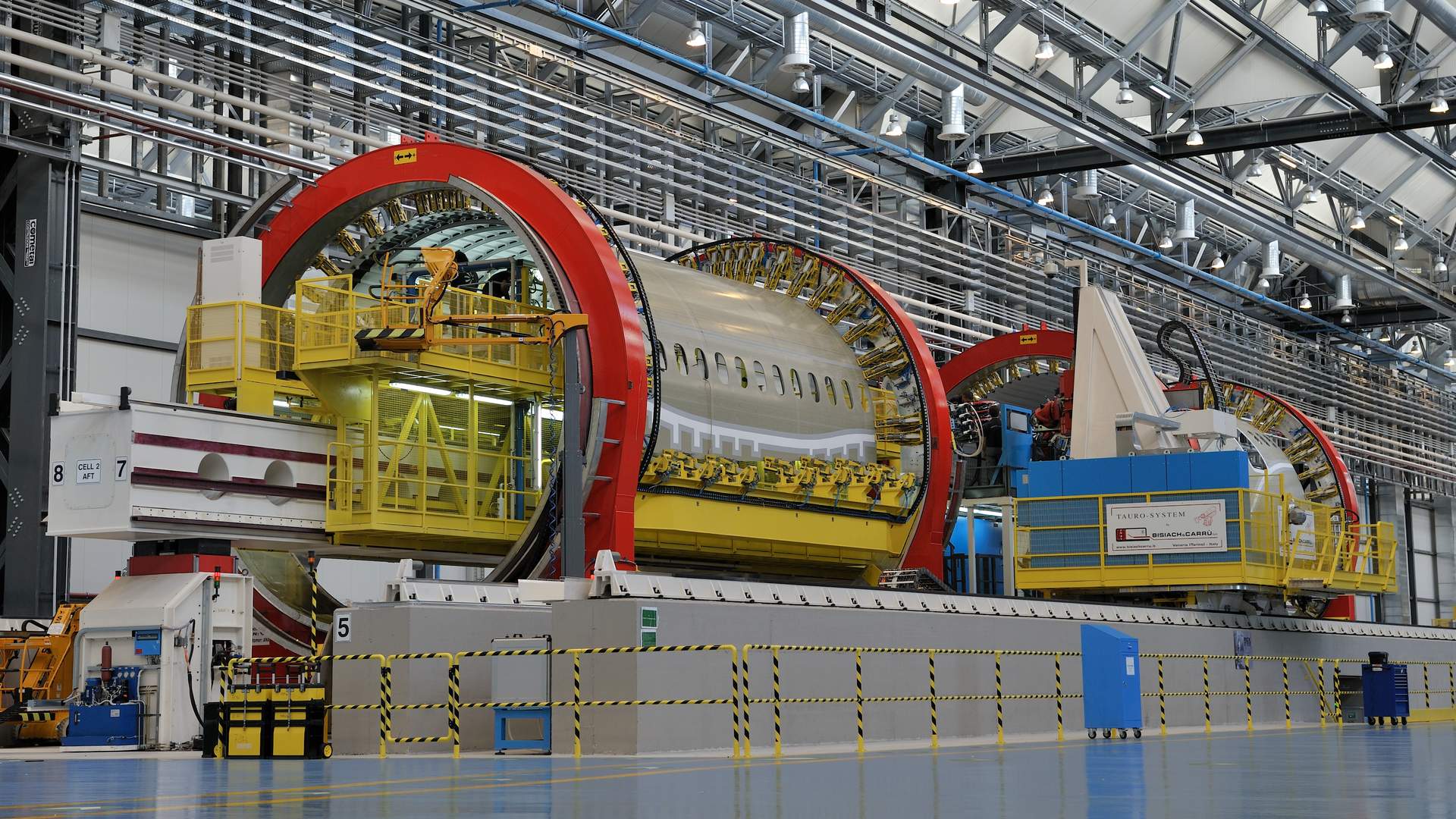

These two companies are now believed to be at the centre of an investigation in Italy, involving non-conforming Boeing 787 parts. MPS and Processi Speciali had to supply parts made of titanium and aluminium, which they then processed further.

Suspect Boeing Parts in Italy – Lower-Grade Metals?

But according to prosecutors in Italy, the two companies used lower grades of titanium and aluminium, to make these Boeing parts. These meant that the parts had “…significantly lower static and stress resistance characteristics, with repercussions on aviation safety”, according to the prosecutors.

Several experts helped prosecutors in Italy and elsewhere identify non-conforming parts that the two companies made for Boeing. In total, prosecutors now believe that the companies supplied 4,829 titanium components, plus 1,158 other parts made using aluminium. That’s up from 4,189 components in total, that we knew from earlier reports (in December 2021).

Boeing has already identified aircraft that include suspect parts from the two subcontractors in Italy. It appears that these parts are primarily fasteners (nuts, bolts, washers). Boeing reassured operators that this doesn’t represent an immediate safety-of-flight issue, but their longevity could be a factor.

Removing all of these parts from stored and in-service aircraft was a time-consuming and very costly process, something that prosecutors are factoring into the proceedings. However, the case hasn’t yet made it to court. A lawyer for the Ingrossos stated that they believe that “they have acted respecting fully the law”.

One of the many criticisms on Boeing over the past couple of decades is a push to outsource much of its parts manufacturing and assembly outside its own installations in the United States. Keeping quality control in check when dealing with an expanding network of suppliers has been a key part of this challenge.

1 comment

codyhaul

There’s a reason I call the Dreamliner “the aircraft built by outsourcing”, and I don’t mean it in a good way