Following a meeting with Boeing CEO Dave Calhoun, the FAA gave Boeing 90 days to present a plan to tackle its quality control issues.

Late in February, FAA Administrator Mike Whitaker had a day-long meeting with the Boeing CEO. In a later statement, Whitaker said that Boeing needs to make “real and profound improvements” as it addresses its quality control issues.

The plan that the FAA expects to see will have milestones that the manufacturer will have to hit over time. Calhoun acknowledged the plan, saying that the company “has a clear picture of what needs to be done”.

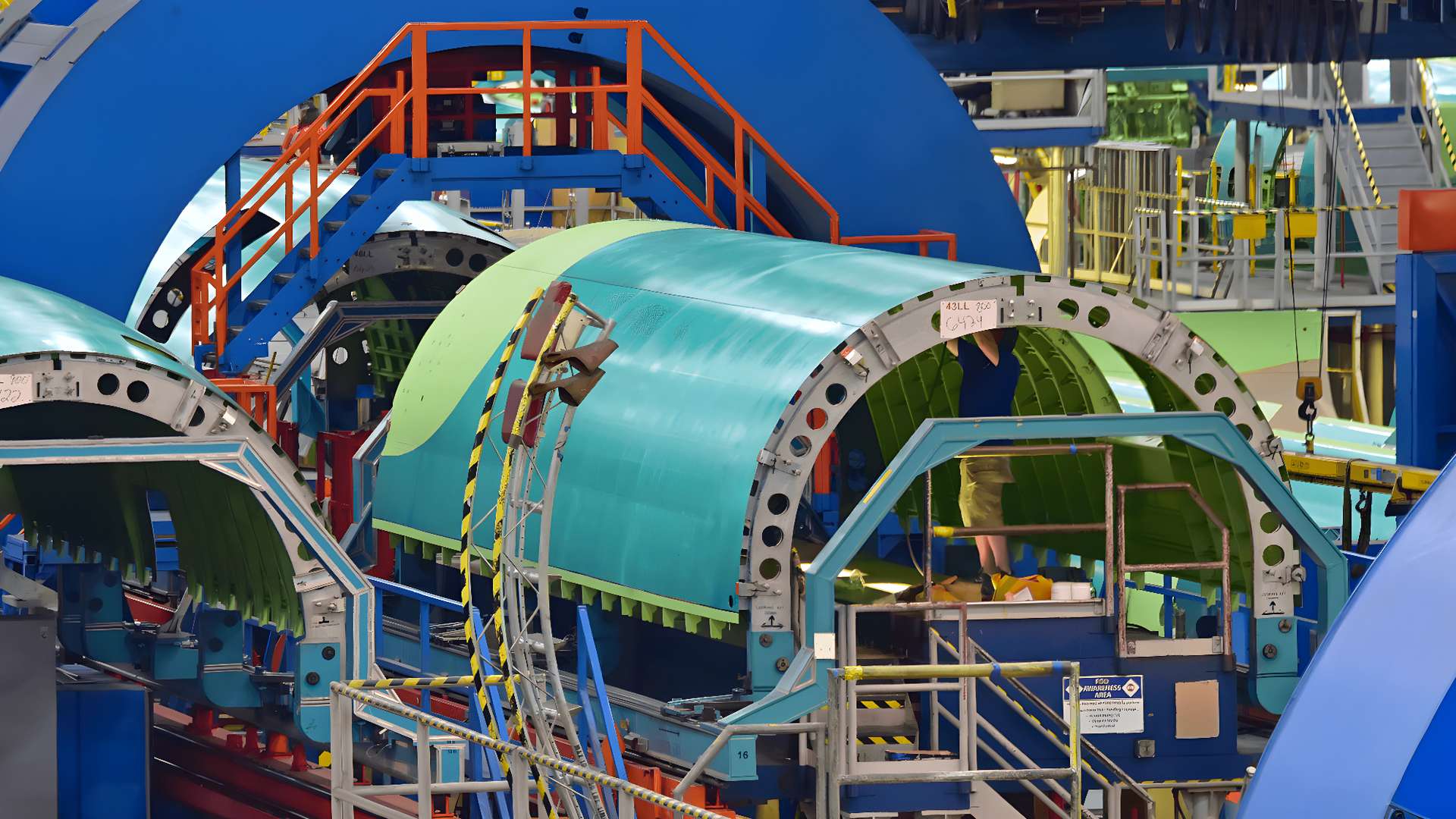

More recent news suggests that Boeing is pushing back its previous plans to increase aircraft production, as it focuses on its quality control. Before the 737 MAX-8 blow-out last January, Boeing wanted to hit a monthly production rate of 42 737s by February.

Production Rates Go Down While Boeing Addresses Quality Control

That obviously didn’t happen. But despite an FAA cap of 38 737s per month, the manufacturer still wanted its suppliers to continue operating with the 42-jet monthly rate in mind, in an effort to help parts production recover and build some inventory. In August this year, Boeing previously targeted a monthly rate of 47 737s.

It now seems that this new focus on quality is leading Boeing to push its August production rate target to January next year. Plus, another target to produce 52 737s per month, is now pushed back to June 2025.

Boeing has tied these targets, along with one for 57 737s for August 2025 (now February 2026) with its goal to hit $10 billion in free cash flow, by 2025-26. Despite the FAA’s closer look at quality control, Boeing still aims to reach this goal.

However, there are a number of ways for Boeing’s plans to go awry. It is too early to tell what effect Boeing’s purchase of Spirit AeroSystems might have on these targets. That’s assuming that such a deal actually goes through.

Meanwhile, Airbus continues to increase its single-aisle aircraft production. But its efforts alone aren’t enough to meet the demand for new airliners, in a market that is missing around 3,000 aircraft, following the pandemic-era loss of production and early retirements.

3 comments

Metin

Of course not, making money from stcok market is overall important over safety, David is getting rich, son of a bitch

Eduard Amorós i Wahl

As I understand it, Boeing is not supposed to fix the problem in 90 days. What it is supposed to do is to present a plan. This is 100% an industrial standard. In order to tackle a problem, you set up a plan, with deadlines and objectives, along with a methodology to analyse the effectiveness of the corrective measures all along the duration of the plan. I insist, this is 100% common practice in industry.

My background is in railroad industry (in Europe), but it works in the exact same way. I know, because in addition to fixing electricals in locomotives and passenger rail cars, I also write company procedures and work in quality assurance.

I can imagine that the American air safety administration will require, at intervals, some feedback from Boeing’s recovery plan: registers, KPI’s, and also modifications to the plan based on observations… to make sure everything stays on track.

John

Hopefully they get it together really, really fast.

Government wants autonomous KC-135’s.

I live under a refueling air pattern.