Boeing has reportedly informed the FAA that a number of 787s that have not yet entered service were built with incorrectly installed parts.

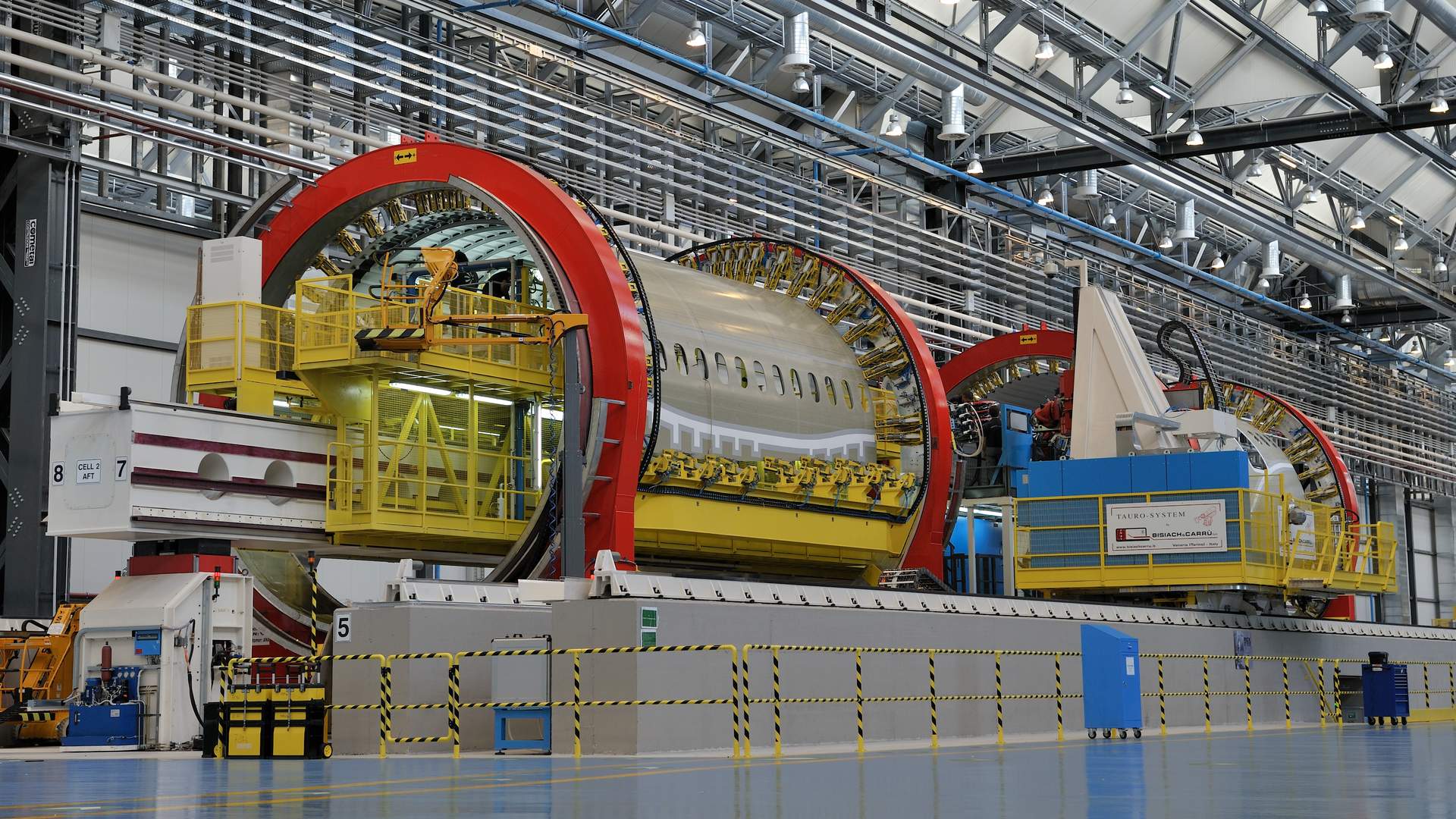

The American manufacturer discovered that nuts and bolts used to attach fuselage sections of the 787 to other structural elements of the aircraft were not torqued correctly. The issue involves as many as 900 parts per aircraft, for an undisclosed number of Boeing 787s.

It is not clear if Boeing discovered these mis-installed parts in 787s that it produced recently or not. Boeing has a backlog of older 787s undergoing checks because of separate quality control issues. It is possible that this issue could involve these older 787s.

The error in the installation of these fuselage parts reportedly involves 787s that Boeing made in North Charleston, South Carolina. This could indicate that they are newer, since that older backlog of 787s was made in both N. Charleston and Everett.

Boeing 787s, Parts, and FAA Oversight

According to Reuters, the mis-installed parts in these 787s were torqued from the wrong side. Rather than torquing the nuts securing the bolts, workers torqued the bolts themselves, instead.

According to Boeing, this parts issue doesn’t affect the delivery schedule of newer 787s to their customers. Following the Alaska Airlines 737 MAX-9 door plug blowout last January, Boeing has already been under intense scrutiny.

It isn’t clear if this additional scrutiny had a role in the discovery of this latest issue. Separately, the FAA itself is under scrutiny, with some stakeholders arguing that its oversight over Boeing hasn’t been good enough.

Current FAA Administrator Mike Whitaker recognized this to be the case recently, adding that the regulator is now monitoring Boeing much more closely. He also said that this situation is permanent, and will continue even after they permit Boeing to increase 737 production.

However, such an increase (beyond 38 aircraft per month) isn’t likely to happen “in the next few months”, according to Whitaker. And in any case, Boeing isn’t close to that production rate today.

3 comments

Iskender Kutlucinar

This really bad for mechanics they have, they need more training, even a decent car mechanic knows how to torque correctly!

Parrett Family

Ugh. Boeing has been failing recently.

Patrick Butler

The biggest problem as I see it. There is no tradition of aviation manufacturing in South Carolina. Something as simple as torquing hardware from the nut side is not in anyone’s institutional memory. In aviation it makes a difference.